OUR PRODUCTS

Processing Machine

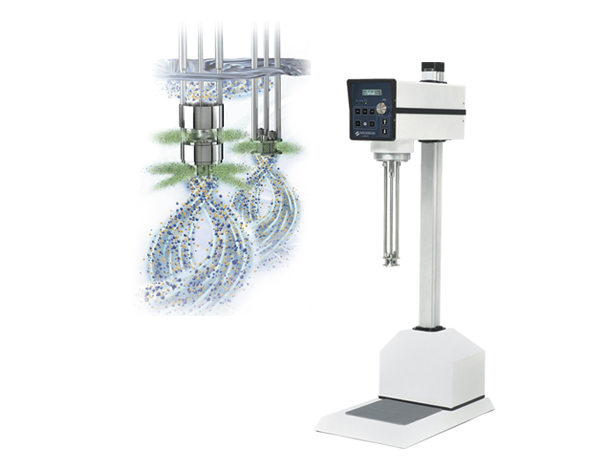

Laboratory Mixer

Ideal for all laboratory work, research and development, QA analysis and small scale production in all industries.

High Shear Mixer Homogenizer

This precision-machined mixing workhead offers great versatility by allowing any machine to perform a wide range of mixing operations.

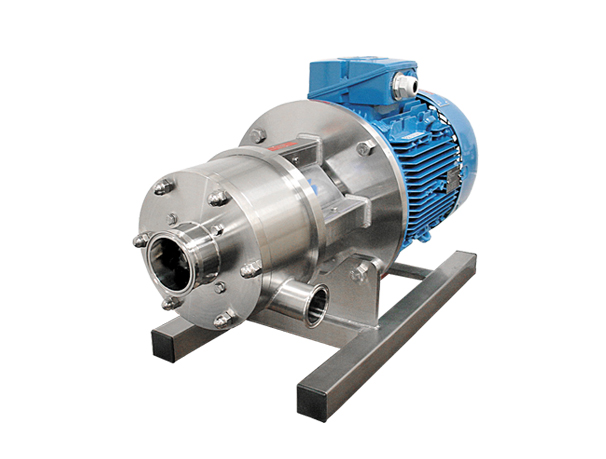

Bottom Entry Mixerr

These high shear mixers are typically used in conjunction with a slow speed anchor stirrer or scraper unit for high viscosity products.

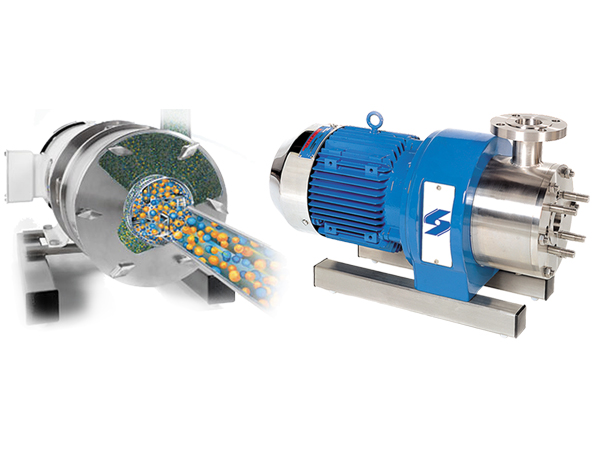

High Viscosity In-Line Mixer

Silverson’s High Viscosity (HV) In-Line Mixers offer exceptional flow rates and the ability to process higher viscosity products.

In-Line Mixer for General Duty

The Silverson Ultra Hygienic series of multipurpose In-Line mixers is able to perfom the widest variety of applications.

Flashblend Powder / Liquid Mixer

The Flashblend is designed to incorporate powders on a continuous and semi-continuous basis at rates of up to 15,000 kg/hour.

Disintegrator

Silverson’s mighty Disintegrator 2500 mixing system will disintegrate, solubilise or disperse the largest of solids - up to 1 metre across - in a single operation.

Vacuum Mixer Homogenizer

Vacum Mixer Homogenizer designed for the production of stable emulsions creams, milk, gels, balms, lotions, ointments, toothpastes, etc.

Fluid Bed Dryer Lab

Tangential is the latest technology in fluid bed granulation which can cut off by 50% - 75% process time compared to traditional technology (Top spray and bottom spray), giving the highest operation efficiency.

Granulation Line for Production Scale

Uniquely qualified to provide state of the art integrated powder handling and processing line to supply better product than the best and increase the powder productivity efficiently.

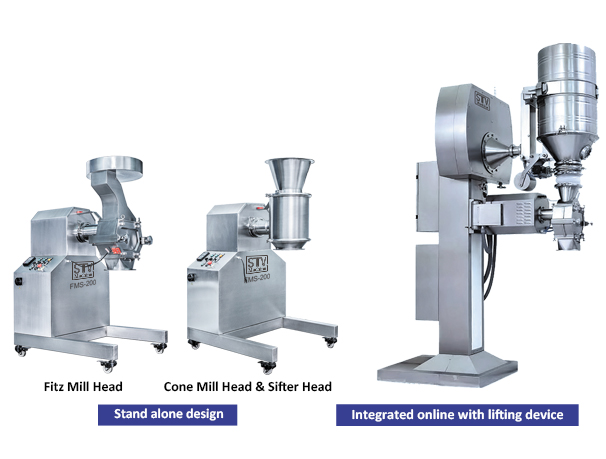

Free Drive Milling & Sifting

One Driver with Interchangeable Head with 3 Function: Fitz Mill Head (Hammer Mill), Cone Mill Head for Sizing (Wet & Dry), and Sifter Screen on Cone Mill Head (for Sieving Function)

Roll Compaction System

The TFC Roll Compactor utilizes a cantilevered roll design and features a vertical tapered feed screw system and the DP/DPS compaction rolls.

Tablet Coating System for Lab/Pilot Scale

The R&D Coating machine is used for film coating or sugar coating in laboratory or pilot production.

Tablet Coating System for Production Scale

Machine is available for both film coating and sugar coating, using personalized drum sytem for best efficiency, available for time-release tablet.

Washing Machine for Vials and Ampoules

HD-Ultrasonic Washing Machine Series ensure complete washing that prevents any contamination in/outside of any cylindrical containers such as vials and ampoules under compliance of GMP regulations.

Sterilizing and Drying Tunnel

HD-SDT Series are designed to sterilize and depyrogenate ampoules or glass vials by a laminar flow of hot air at up to 350 degrees.

Ampoule Filling and Welding Machine

This Machine can carry out the procedures such as ampoules conveying, front gas charging, filling, rear gas charging, preheating and welding.

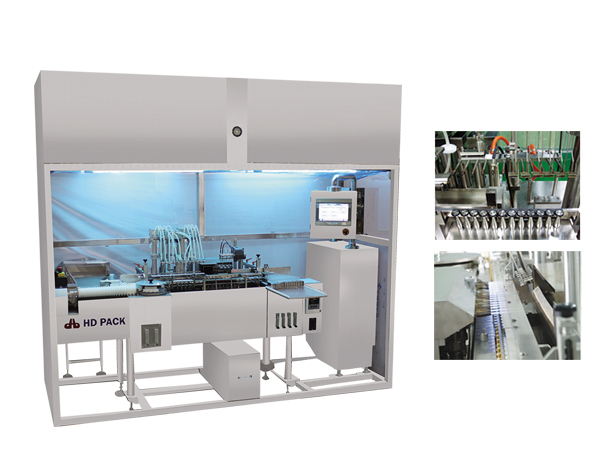

Vial Filling and Rubber Stopping Machine

HD-VFS Series are in-line filling and stopper machine with continuous motion positive in-line transport system and suitable for filling liquid solution into cylindrical vials and rubber stopper insertion.